Steel DIN Rail Mounting Clips

- Sturdy metal construction

- Versatile design

- Clips onto 35mm DIN rail

- Several styles available

- DIN Rail sold separately

General Description

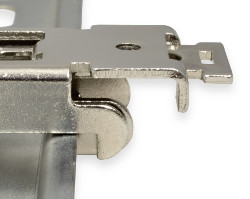

These sturdy steel DIN rail mounting brackets are useful for mounting a wide variety of devices onto standard 35 mm DIN rail. They feature a flat mounting surface and pre-drilled mounting holes, which, depending on the model, are threaded (M4 x 0.7mm) and/or unthreaded. These brackets very easily attach and detach from a DIN rail while maintaining high rigidty and load capacity: the bracket latches onto both the top and bottom lips of the rail with the fixed (non spring-loaded) end of the bracket on the top of the rail to bear the weight of its device.

Several models are available. They vary in size, mounting hole style, ways in which they can be detached from a DIN rail, and amount of rail clearance. The differences between each model can be seen below:

We also offer a Right Angle version which can save significant DIN rail space by mounting devices perpendicular to the rail.

Rail Clearance / Installation & Removal Method

Clips are offered in two different versions, which impacts both how it can be installed/removed, as well as its rigidity on the rail:

Click image to enlarge.

Click image to enlarge.

Click image to enlarge.

Click image to enlarge.The tighter rail clearance of the Latch Release version restricts movement of the bracket on the rail, making the assembly more rigid for unusual side loading or rotational forces. This can be helpful, for example, when dealing with arrangements that have unusually stiff cables.

Click image to enlarge.

Click image to enlarge.

Click image to enlarge.

Click image to enlarge.

Unusually Stiff Cable Assembly

Click image to enlarge.

Click image to enlarge.

Unusually Stiff Cable Assembly

Click image to enlarge.

Click image to enlarge.Removal from a Rail

Removing Lift & Pivot Clips: DINM21, DINM22, DINM23, DINM23T3, DINM23U40, DINM24

Typically the simplest method to remove the Lift & Pivot clips is to lift up on the mounted device, pivot the top of the device out away from the rail, and lower the entire device off the rail. This technique is possible because of the larger amount of rail clearance and does not require access to the release handle, which makes this method easier, especially if a bulky device is mounted to the clip and is blocking easy access to the latch tabs. However, you can also use the Latch Release method to remove these brackets if desired.

Click image to enlarge.

Click image to enlarge.Removing Latch Release Clips: DINM20, DINM23LR

Because these models have tighter rail clearance, the Latch Release handle must be actuated in order for the bracket to be able to move far enough away from the rail to detach. For this reason, the "lift and pivot" method will not work.

Click image to enlarge.

Click image to enlarge.Mounting Hole Style

DINM20, DINM23U40, DINM24

The DINM20 and DINM23U40 have two and the DINM24 has four unthreaded 4mm diameter mounting holes. The holes in this bracket can accommodate M4 (M4 x 0.7mm) machine screws, #6 machine screws, or #6 sheet metal screws. Please note that the small head size M4 hardware (sold separately below) will be needed in order to work well with the DINM20 and DINM23U40 clips if the screw heads are located on the back side of the clips.

DINM23T3

The DINM23T3 contains M3 threaded (M3 x 0.5mm) mounting holes. Winford does not yet sell screws for these clips, but they are available from many hardware vendors.

DINM21, DINM22, DINM23, DINM23LR, DINM24

The DINM21, DINM22, DINM23, DINM23LR, and DINM24 contain M4 threaded (M4 x 0.7mm) mounting holes. Winford offers M4 machine screws (sold separately below) that work well with these clips.

Click image to enlarge.

Click image to enlarge.| DINM20 | DINM21 | DINM22 | DINM23 | DINM23LR | DINM24 | |

|---|---|---|---|---|---|---|

| Width | 44.2 mm | 44.2 mm | 19 mm | 25 mm | 25 mm | 52 mm |

| Mounting Hole Style | two unthreaded | six M4 threaded | two M4 threaded | two M4 threaded | two M4 threaded | two M4 threaded & four unthreaded |

| Installation/Removal Method | Latch Release | Lift & Pivot OR Latch Release |

Lift & Pivot OR Latch Release |

Lift & Pivot OR Latch Release |

Latch Release | Lift & Pivot OR Latch Release |

| Tight Rail Clearance | yes | no | no | no | yes | no |

Product Documents

Product Details

- Nickel-plated steel

- Sturdy metal construction

- Clips onto 35mm DIN rail

- Several styles available

- DIN Rail sold separately

Pricing and Ordering

| Product # | Description | 1+ | 10+ | 100+ | RoHS | Buy Now |

|---|---|---|---|---|---|---|

| DINM20 | DIN Rail Mounting Clip, Steel, 44.2mm Width, Unthreaded Holes, Latch Release | $3.60 | $3.35 | $2.95 | Yes | |

| DINM21 | DIN Rail Mounting Clip, Steel, 44.2mm Width, M4x0.7mm Threaded Holes, Lift and Pivot | $3.60 | $3.35 | $2.95 | Yes | |

| DINM22 | DIN Rail Mounting Clip, Steel, 19mm Width, M4x0.7mm Threaded Holes, Lift and Pivot | $3.50 | $3.25 | $2.85 | Yes | |

| DINM23 | DIN Rail Mounting Clip, Steel, 25mm Width, M4x0.7mm Threaded Holes, Lift and Pivot | $3.50 | $3.25 | $2.85 | Yes | |

| DINM23LR | DIN Rail Mounting Clip, Steel, 25mm Width, M4x0.7mm Threaded Holes, Latch Release | $3.50 | $3.25 | $2.85 | Yes | |

| DINM23T3 | DIN Rail Mounting Clip, Steel, 25mm Width, M3x0.5mm Threaded Holes, Lift and Pivot | $3.50 | $3.25 | $2.85 | Yes | |

| DINM23U40 | DIN Rail Mounting Clip, Steel, 25mm Width, 4mm Unthreaded Holes, Lift and Pivot | $3.50 | $3.25 | $2.85 | Yes | |

| DINM24 | DIN Rail Mounting Clip, Steel, 52mm Width, M4x0.7mm Threaded and Unthreaded Holes, Lift and Pivot | $3.60 | $3.35 | $2.95 | Yes |

| Quantity | Price |

|---|---|

| 1+ | $3.60 |

| 10+ | $3.35 |

| 100+ | $2.95 |

| Quantity | Price |

|---|---|

| 1+ | $3.60 |

| 10+ | $3.35 |

| 100+ | $2.95 |

| Quantity | Price |

|---|---|

| 1+ | $3.50 |

| 10+ | $3.25 |

| 100+ | $2.85 |

| Quantity | Price |

|---|---|

| 1+ | $3.50 |

| 10+ | $3.25 |

| 100+ | $2.85 |

| Quantity | Price |

|---|---|

| 1+ | $3.50 |

| 10+ | $3.25 |

| 100+ | $2.85 |

| Quantity | Price |

|---|---|

| 1+ | $3.50 |

| 10+ | $3.25 |

| 100+ | $2.85 |

| Quantity | Price |

|---|---|

| 1+ | $3.50 |

| 10+ | $3.25 |

| 100+ | $2.85 |

| Quantity | Price |

|---|---|

| 1+ | $3.60 |

| 10+ | $3.35 |

| 100+ | $2.95 |

Mounting Hardware

We offer metric mounting hardware for the threaded holes on the DINM21, DINM22, DINM23, DINM23LR, and DINM24 clips.Small Pan Head metric hardware is also available for the DINM20 and DINM23U40 clips.

Pricing and Ordering

| Product # | Description | 1+ | 5+ | 10+ | RoHS | Buy Now |

|---|---|---|---|---|---|---|

Pan Head (Standard head size): |

||||||

| SCMAPP-M4-A-8-100 | Screw, Machine, Pan Head, Phillips, M4 x 0.7mm Thread, 8mm Length, Bag of 100 | $5.70 | $5.20 | $4.60 | Yes | |

| SCMAPP-M4-A-10-100 | Screw, Machine, Pan Head, Phillips, M4 x 0.7mm Thread, 10mm Length, Bag of 100 | $5.75 | $5.30 | $4.70 | Yes | |

| SCMAPP-M4-A-12-100 | Screw, Machine, Pan Head, Phillips, M4 x 0.7mm Thread, 12mm Length, Bag of 100 | $5.80 | $5.35 | $4.75 | Yes | |

Pan Head (Small head size): |

||||||

| SCMAPP-M4-B-8-100 | Screw, Machine, Small Pan Head, Phillips, M4 Thread, 8mm Length, Bag of 100 | $5.45 | $5.05 | $4.50 | Yes | |

| SCMAPP-M4-B-10-100 | Screw, Machine, Small Pan Head, Phillips, M4 Thread, 10mm Length, Bag of 100 | $5.50 | $5.10 | $4.60 | Yes | |

| SCMAPP-M4-B-12-100 | Screw, Machine, Small Pan Head, Phillips, M4 Thread, 12mm Length, Bag of 100 | $5.55 | $5.15 | $4.65 | Yes | |

Flat Head: |

||||||

| SCMAFP-M4-A-8-100 | Screw, Machine, Flat Head, Phillips, M4 x 0.7mm Thread, 8mm Length, Bag of 100 | $4.80 | $4.35 | $3.85 | Yes | |

| SCMAFP-M4-A-10-100 | Screw, Machine, Flat Head, Phillips, M4 x 0.7mm Thread, 10mm Length, Bag of 100 | $5.35 | $4.90 | $4.30 | Yes | |

| SCMAFP-M4-A-12-100 | Screw, Machine, Flat Head, Phillips, M4 x 0.7mm Thread, 12mm Length, Bag of 100 | $5.40 | $4.95 | $4.40 | Yes | |

| Quantity | Price |

|---|---|

| 1+ | $5.70 |

| 5+ | $5.20 |

| 10+ | $4.60 |

| Quantity | Price |

|---|---|

| 1+ | $5.75 |

| 5+ | $5.30 |

| 10+ | $4.70 |

| Quantity | Price |

|---|---|

| 1+ | $5.80 |

| 5+ | $5.35 |

| 10+ | $4.75 |

| Quantity | Price |

|---|---|

| 1+ | $5.45 |

| 5+ | $5.05 |

| 10+ | $4.50 |

| Quantity | Price |

|---|---|

| 1+ | $5.50 |

| 5+ | $5.10 |

| 10+ | $4.60 |

| Quantity | Price |

|---|---|

| 1+ | $5.55 |

| 5+ | $5.15 |

| 10+ | $4.65 |

| Quantity | Price |

|---|---|

| 1+ | $4.80 |

| 5+ | $4.35 |

| 10+ | $3.85 |

| Quantity | Price |

|---|---|

| 1+ | $5.35 |

| 5+ | $4.90 |

| 10+ | $4.30 |

| Quantity | Price |

|---|---|

| 1+ | $5.40 |

| 5+ | $4.95 |

| 10+ | $4.40 |

Accessories

We offer loop lanyards for use in ease-of-access to our metal DIN clip release latches.Pricing and Ordering

| Product # | Description | 1+ | 10+ | 25+ | RoHS | Buy Now |

|---|---|---|---|---|---|---|

| LSLL01A-4020 | Lanyard, Loop, Approx 4" Hand Loop, Approx 2" Device Loop | $1.75 | $1.25 | $1.00 | No |

| Quantity | Price |

|---|---|

| 1+ | $1.75 |

| 10+ | $1.25 |

| 25+ | $1.00 |

All of the above items are normally stocked. Please call us if you need to verify availability for a specific quantity, or for pricing at higher quantities. Please visit our ordering page for our ordering policies and a list of ordering methods.